CHEMCAD NXT

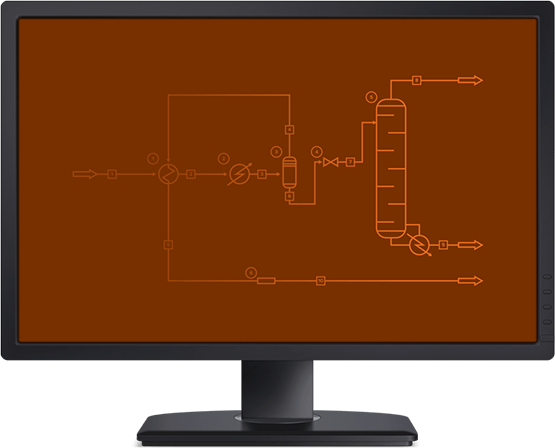

Broadening the capabilities of chemical engineers everywhere with enhanced process simulation software, CHEMCAD is designed to help you drive productivity, accomplish day-to-day tasks, and tackle the toughest chemical process models. CHEMCAD is flexible enough to handle virtually any challenge that comes your way.

What is CHEMCAD?

CHEMCAD is an integrated suite of intuitive chemical process simulation software that fits into the chemical engineering workflow and supercharges an engineer's efficiency. Perhaps most significantly, it continues to evolve to meet the ever-expanding needs of chemical engineers.

BENEFITS

- Highly customizable, flexible, and affordable

- All modules work within a single graphical user interface for seamless interaction

- Adapts to how you approach engineering challenges

- Appealing graphics and reports are easy to export to third-party software

- Easily integrates into chemical engineering computing environment

- Personalized technical support second to none

Unmatched Support

As advanced and intuitive as CHEMCAD is, it's the team of people behind the software who make the biggest difference. Our outstanding technical support engineers understand chemical engineers' challenges, and are happy to help you use the software to address every task, every project, every job.

Take advantage of:

- Phone and e-mail access to high-level customer support engineers

- Customer portal with robust knowledge base

- Ticketing system to track feature requests and software improvements

- Helpful library of training videos

CHEMCAD Features

- User-customizable panes

- Workspace to create and work with process flow diagrams (PFDs)

- Message pane that displays diagnostics as you work with a simulation

- CHEMCAD Explorer pane that makes navigating simulations easy

- Palette pane for easy drag-and-drop access to unit operations and symbols

- Tabbed command ribbon that provides easy access to common tasks

Streamline Day-to-day Engineering Tasks

Harness the productivity advantage with CHEMCAD and complete daily tasks more quickly with process simulation software.

EQUIPMENT SIZING

- Heat exchangers

- Vessels

- Piping/valves - pressure drop/line sizing

- Also available for pumps, safety relief devices, and column trays and packing

Thermophysical Property Calculations:

- Bubble/dew points

- Component family analyses

- Data regression

- Pure components

- Binary interaction parameters

Facilitate Large Projects

Equip your team with CHEMCAD's integrated process simulation modules so they can work

- Process development

- Fitting reaction kinetics from experimental data

- Direct lab experiments and pilot plant runs

- Scale up from lab to pilot, and pilot to production

- Dynamic simulations

- Control system design/checkout

- Safety

analyses

- Process intensification studies

- Energy efficiency/optimization

- Data reconciliation

- Process economics

Manage Smaller Projects

Streamline processes in smaller projects and improve workflow with CHEMCAD, featuring an intuitive interface that helps you save time.

Troubleshooting/Process Improvement:

- Equipment design

- Distillation with mass transfer calculation

- Relief system design/rating with DIERS

- Reporting

- Equipment/process costing

- Process safety analyses

- Regulatory compliance reports

- Heat and material balance reporting

- Model potential customer systems in order to sell equipment and/or processes

Employ Integrated Solutions

Seamlessly integrate CHEMCAD process simulation software with other programs and accelerate progress in larger, ongoing projects.

- Integrated solutions

- Process/plant performance monitoring

- Model predictive control

- Real-time optimizations

- CHEMCAD as the engine for other applications

- Microsoft Visual Basic® for Applications

- Excel "wrappers" for simulations

- Operator training systems

Support Links

We go the extra mile when it comes to providing reliable and comprehensive support. Discover our vast range of helpful CHEMCAD resources including release notes, Support Center details and flexible training opportunities.

System Requirements

We recommend the following mimimum system configuration for on-premises CHEMCAD installation, to achieve the best results with the software:

- Processor speed: 1 GHz or faster, 32- or 64-bit

- Operating system: Windows 7 or later (all 32- and 64-bit versions)

- RAM: 1 GB for 32-bit, or 2 GB for 64-bit

- Video card: DirectX 9 graphics device with WDDM 1.0 or higher driver

- Display resolution: 1920 x 1080 or higher

- Hard disk space: 16 GB (32-bit) or 20 GB (64-bit) for installation,

1 GB free space recommended - Productivity software: Some features require Microsoft Office®

Looking for CHEMCAD 8?

Select customers have access to CHEMCAD 8, including but not limited to legacy customers and universities.

Free Trial

Give CHEMCAD a test run and see why enhanced process simulation is a true step change for productivity in chemical engineering planning and design.

Find a Representative

Search for a trusted CHEMCAD representative in or around your area and inquire about our suite of integrated chemical engineering simulation software.