Using CHEMCAD to calculate flow rate as a function of pressure

How do you approach engineering challenges involving hydraulic balance in piping networks? The right tools are essential when designing and evaluating a flare network or relief piping system, calculating flow and pressure drop through equipment, or diagnosing leak problems in plants.

How do you approach engineering challenges involving hydraulic balance in piping networks? The right tools are essential when designing and evaluating a flare network or relief piping system, calculating flow and pressure drop through equipment, or diagnosing leak problems in plants.

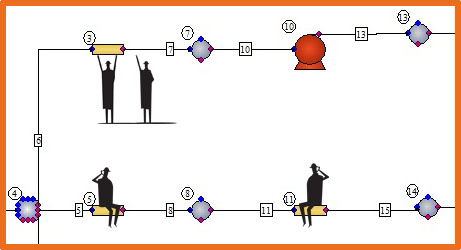

CHEMCAD can help with these challenges, by performing hydraulic balance and pressure calculations in piping networks. The program predicts pressure drop, flow rate as a function of pressure, choked flow, and backflow; for more complex systems, the program also calculates pressures and flow distribution through different branches in pipelines based on pressure balance.

If enough variables are specified in the simulation, CHEMCAD can simultaneously calculate the unknown pressures and/or flow rates throughout the model.

CHEMCAD also leads users to specify the geometry in pumps, valves, compressors, and fittings, and hydraulic resistances in pipes, to enable estimation of the pressure balance as a function of the known variables.

The back pressure on valves, pipes, and pumps affects pipelines’ upstream and downstream conditions. Reverse flow can damage equipment, contaminate fluids, and present a serious risk to health and safety. CHEMCAD can predict flow direction, backflow, or reverse flow by simultaneously solving the pressure balance throughout the entire piping network; it also calculates the flow that pumps and compressors can handle using inlet pressures, outlet pressures, and performance curves.

If you’re ready to start setting up piping networks in CHEMCAD, contact your sales or support representative for more information.